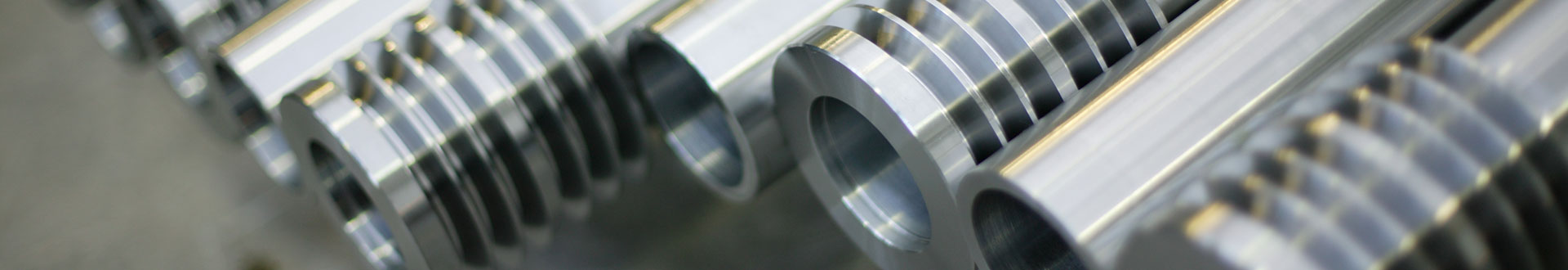

Ranieri srl, precision mechanical turning parts producer, realizes high quality products using daily controls to satisfy its customers needs.

The quality of our products is our main goal in order to maintain a leading position in an increasingly demanding market.

Ranieri satisfies its customers, even the most demanding ones, through its high quality products and it is committed to guarantee always a better service.

PRECISION, QUALITY AND COMPETENCE MAKE US DIFFERENT

The company works on 3 shifts, guaranteeing fast delivery times at very competitive prices.

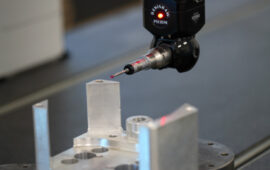

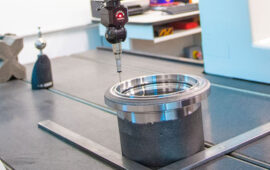

Metrological Room and Measuring Devices

Ranieri has a modern and well-equipped metrological room for all instrument and parts calibration and control (in compliance with ISO 9001 and the current regulations) including the 3D control equipment.

Ranieri is equipped with:

• new and versatile DEA coordinate measuring machine for 3D components control (maximum size 1600X1000X600 mm)

• a profilometer Mitutoyo C-3000,

• reset counter measuring instruments bench TAR-AL S-500,

• a presetting device Elbo E346,

• parallel plane blocks for the bore meters, micrometers and altimeters calibration.

Ranieri implements all necessary quality control of its products and guarantees to deliver its parts according to customers technical drawing.

Each workstation is equipped with technical instruments, according to the process to be performed:

- Mechanical and digital gauges

- Bore Gauges

- Centesimal or millesimal comparators

- Depth gauges

- Mechanical and digital micrometers

- Threaded plug gauges